What are the differences between Pneumatic (Yokohama type) fenders and foam fenders?

Pneumatic fenders and foam fenders are both types of floating fenders, but they differ significantly in their construction, performance, and usage.

What Are Pneumatic Fenders?

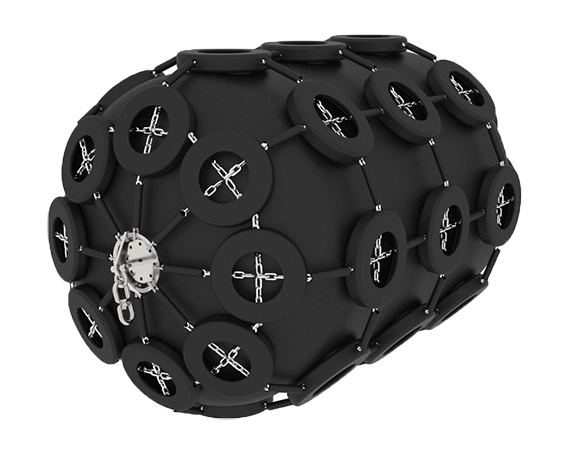

Pneumatic fenders are air-filled rubber fenders. They consist of a wear-resistant rubber outer layer reinforced internally and filled with air. If the rubber exterior is damaged, the fender can deflate, losing its functionality.

What Are Foam Fenders?

Foam fenders, on the other hand, are made from a foam core surrounded by a flexible and wear-resistant Polyurethane layer with fabric reinforcement. Unlike pneumatic fenders, foam fenders will not deflate, even if their Polyurethane coating is damaged.

Performance Differences Between Pneumatic and Foam Fenders

Gradual Energy Distribution

The air inside pneumatic fenders moves freely, allowing for gradual and even energy distribution during angled impacts. This helps reduce concentrated load on the ship’s wall. Foam fenders, however, have a more rigid structure, leading to less uniform load distribution during angled impacts.

Transport and Storage

Pneumatic fenders can be deflated for transportation, saving significant space. For long-term storage, it is recommended to partially inflate pneumatic fenders to maintain the rubber's optimal condition. Foam fenders, being solid, do not offer this flexibility in transport or storage.

Conclusion

Both pneumatic (Yokohama type) fenders and foam fenders have unique advantages depending on the application. Pneumatic fenders excel in versatility, energy distribution, and transport efficiency, while foam fenders offer durability and resilience without the risk of deflation.